Block tackle or pulley calculator.

Multiple pulley system calculator.

Pulley and speed calculator.

The calculator can be used for metric and imperial units as long as the use of units are consistent.

1750 rpm 1000 rpm 3 5 inches d 2 d 2 6 125 inches.

N number of ropes between the sets of pulleys.

Here f a is the anchor load f e is the effort force and f l is the load.

2 20 2014 comments are closed.

The calculator below can be used to calculate effort force in block tackle or pulley construction.

F load n kg lb μ mechanical efficiency of the system.

You can check out our pulley calculator and belt length calculator which is a two pulley system to learn more about.

How to calculate pulley size to set the compressor speed motor rpm x motor pulley diameter divided by driven pulley diameter x band wheel diameter x 3 1416 divided by 12 sfpm before any calculation is made you need to know what the motor rpm is at the shaft either stated on the motor label or taken with a tacho or whatever other means.

Check the circle next to the item you are solving for and enter the remain three items in the spaces provided.

In our example if the left and right ropes were just a single rope we could compare this setup to a pulley system.

This engineering statics tutorial goes over how to calculate tension in a multiple pulley system that is in static equilibrium.

Below is a small calculator that will solve the ratio for you.

If you know any 3 values pulley sizes or rpm and need to calculate the 4th enter the 3 known values and hit calculate to find the missing value.

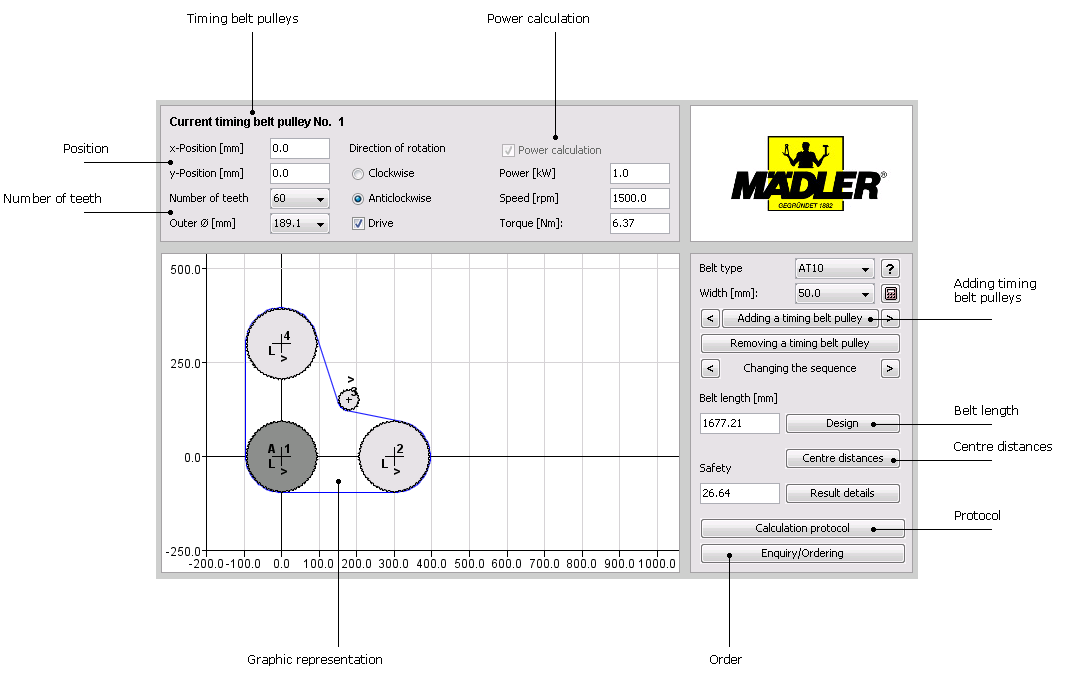

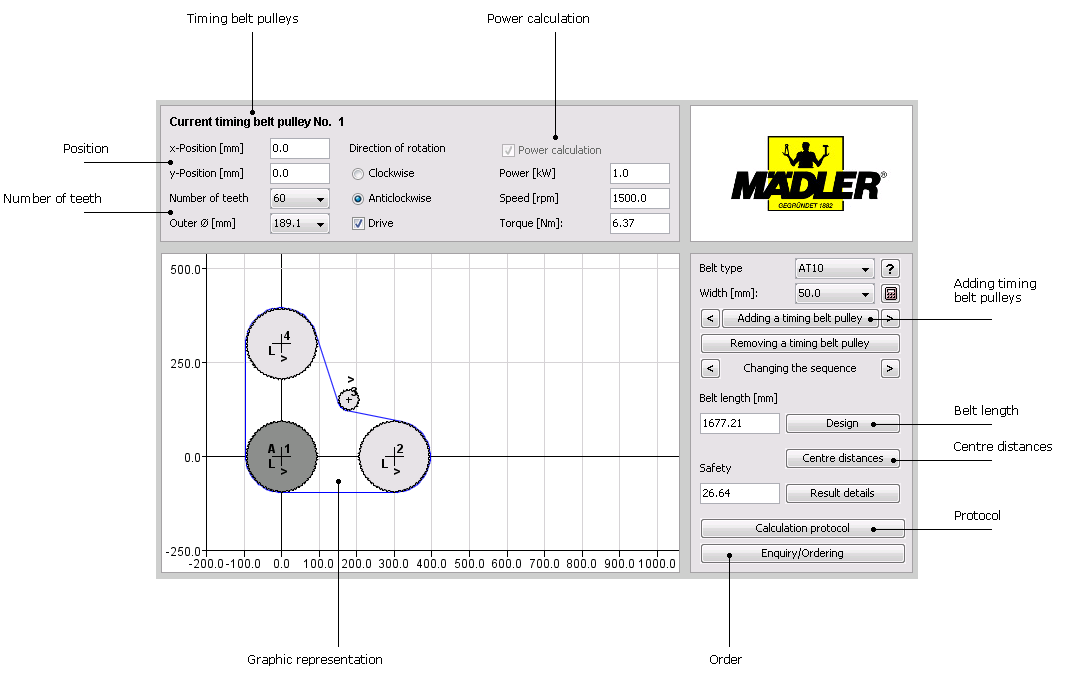

In this calculator there are three main sections dealing with pulleys belts and speed.

A pulley is a simple machine that takes advantage of tension forces in ropes to gain mechanical advantage.

A simple pulley system where the end of the line is attached to the anchor has the mechanical advantage which is equal to 2n where n is the number of moving pulleys.

In each section only one variable is calculated based on the checkbox.

For example if there are four moving pulleys and 8 lines the most left line is used only for change of direction the ma 8.

In the first the driver pulley is the powered usually by an electric motor pulley.

For example if your small pulley is 80mm diameter and spins at 1000 rpm and you need to find the second pulley size to spin it at 400 rpm enter pulley1 80 pulley 1 rpm 1000 pulley 2 rpm 400 and hit calculate to find the second pulley diameter.

The driven pulley is the reactive pulley to the driver.

Now suppose if the applied effort raises the weight w and the pulley p1 by x meters in order to maintain tightness of the string attached to its axle and balance the movement pulley p2 has to move through a distance of 2x meters.

There are 4 cables 3 pulleys.