The latest four page product brochure hybrid ceramic ball bearings profiles the complete line of mrc hybrid ceramic ball bearings ideally suited for large variable speed electric motor applications.

Mrc hybrid ceramic bearings.

Bearings can be used for ge turbines.

Mrc hybrid ceramic bearings for wind turbine generators wind industry challenge.

Take a look at this 6326 hybrid ceramic generator bearing and get in touch with the supplier for a quote right here on spares in motion.

In addition to being excellent electric insulators hybrid bearings have a higher speed capability 1 2 1 5 time limit of rotations compared to steel bearing and will provide longer service life lower friction and a lower level of energy consumption than all steel bearings.

In addition to being excellent electric insulators hybrid bearings have a higher speed capability and will provide longer service life than all steel bearings in most applications.

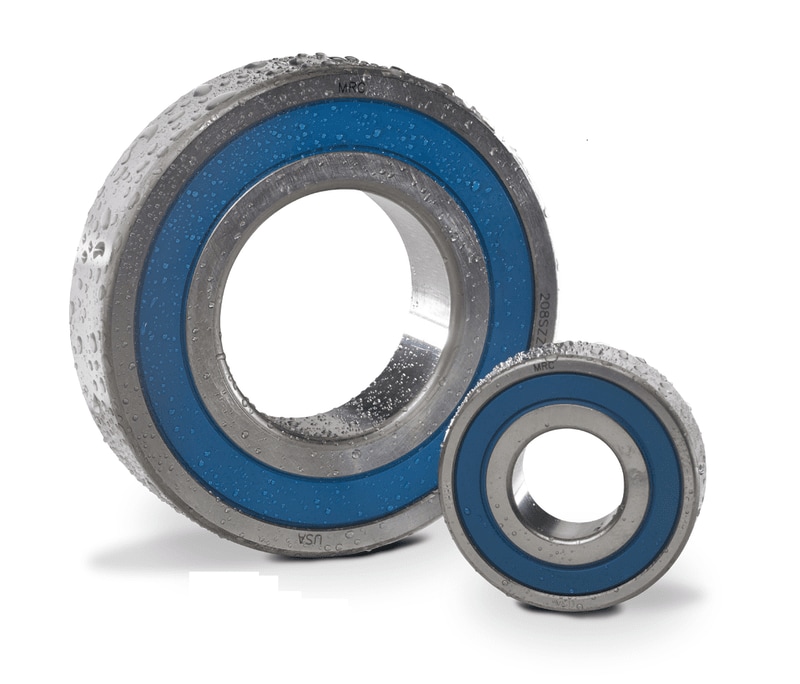

In most cases hybrid bearings can also be supplied with seals shields or low friction seals through the mrc made to order m to program.

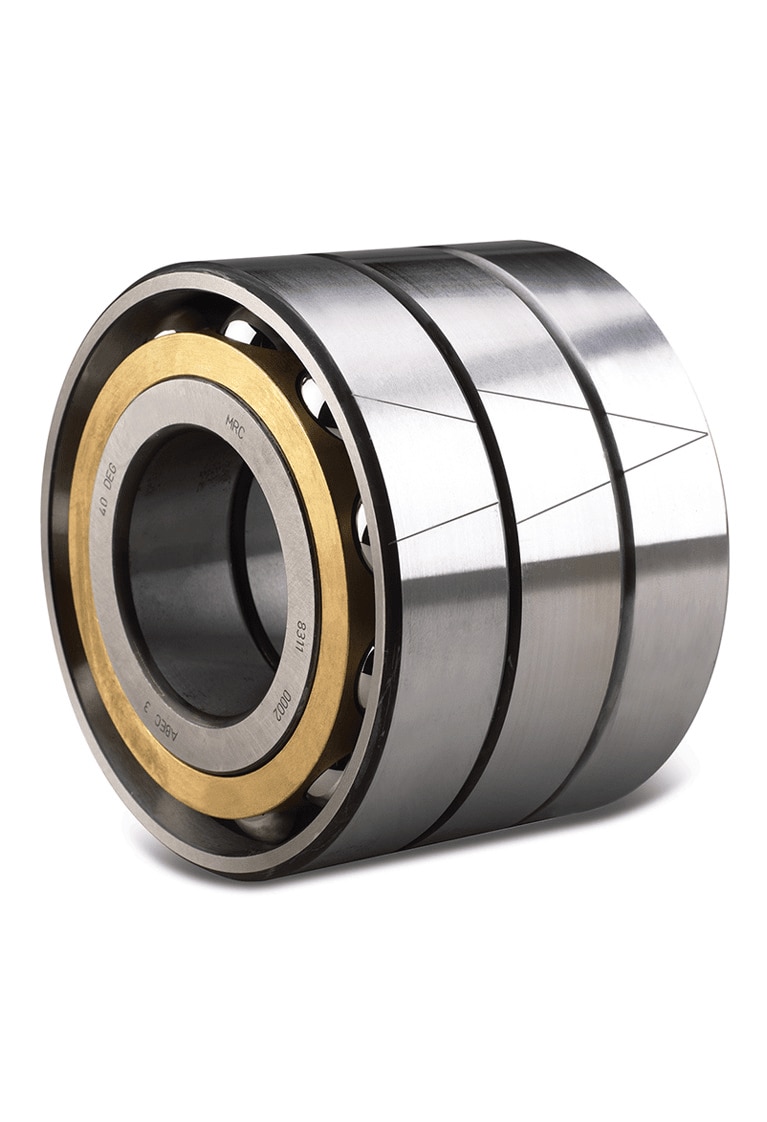

They feature rings of bearing steel and balls of bearing grade silicon nitride.

Mrc r hybrid ceramic ball bearings ideally serve in large variable speed electric motor applications and offer key performance benefits over standard steel ball bearings.

Stray currents one of the main threats to bearings in variable speed wind turbine generators is stray currents.

Mrc hybrid ceramic ball bearings use a combination of traditional 52100 steel rings precision matched with silicon nitride ceramic balls.

The product in product group.

Their design and construction enables hybrids to prevent electrical arcing resist wear run at higher speeds and lower operating temperatures and promote extended service life.

Mrc hybrid ceramic ball bearings hybrid ceramic ball bearings.

This unique ceramic material insulates the bearing against passage of stray electri cal currents while also providing extended.

In addition to being excellent electric insulators hybrid bearings have a higher speed capability and will provide longer service life than all steel bearings in most applications.

Virtually eliminate the risk of electrical erosion rarely is a threat so clear and so easily eliminated.

In addition to those listed other sizes of the 200s and 300s series as well as the 100k s series can be supplied.

Mrc hybrid ceramic ball bearings use a combination of traditional 52100 steel rings precision matched with silicon nitride ceramic balls.

Electrical erosion affects the bearing and the lubricant causing micro pitting and other types of surface damage.

Hyb ceramic balls mrc hybrid ball bearings are stocked in an open version in the sizes listed.

Eventually the bearing can fail.

The majority of bearing failures in variable frequency drive electric motors and large wind turbine generators are linked to the passage of damaging electrical currents.

This spare wind turbine part is manufactured by mrc under part number 326s hyb 3.

Mrc hybrid deep groove ball bearings provide a highly effective solution for both new and installed electric motors and gen erators.