While their hard brittle quality and low energy exclude them from some applications ceramic magnets have won wide acceptance due to their corrosion and.

Motheds to prepare matellic and ceramic magnets.

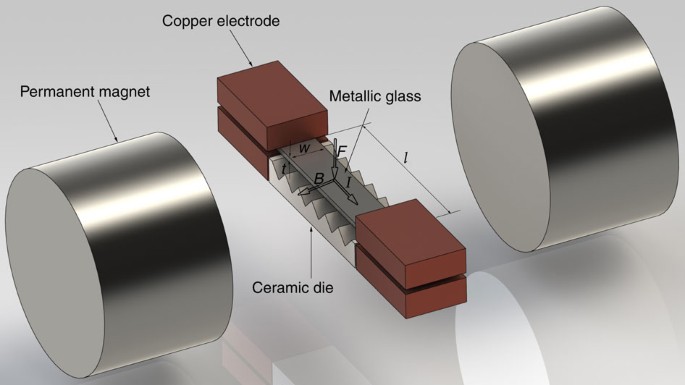

The powder is then compacted in a die by one of two methods.

To make ceramic magnets companies mix these two elements together.

Ceramic or ferrite magnets are produced by calcining a mixture of iron oxide and strontium carbonate to form a metallic oxide.

Ceramic magnets are produced by calcining a mixture of iron oxide and strontium carbonate to form a metallic oxide which is then compacted in a die learn more about ceramic magnet manufacturing methods.

While their hard brittle quality and low energy exclude them from some applications ceramic magnets have won wide acceptance due to their corrosion and demagnetization resistance and low price per pound.

The slurry is compacted in a die in the presence of a magnetic field.

A multiple stage milling operation reduces the calcined material to a small particle size.

Ceramic magnets also known as ferrite magnets were developed in the 1960 s as a low cost alternative to metallic magnets.

Ceramic magnets manufacturing methods ceramic ferrite magnets are produced by calcining a mixture of iron oxide and strontium carbonate to form a metallic oxide.

Thus the fabrication and quality control procedures must involve manipulating and measuring the degree of preferred orientation in the ceramic.

How are ceramic magnets made.

Ceramic magnets are also called hard ceramic magnets or ferric magnets.

Ceramic magnets were less expensive and more powerful and quickly became popular.

A multiple stage milling operation reduces the calcined material to a small particle size.

Ceramic magnets also known as ferrite magnets were developed in the 1960 s as a low cost alternative to metallic magnets.

Originally invented in the 1960s ceramic magnets are man made magnets comprised primarily of iron oxide and strontium carbonate.

These magnets are composed of iron oxide chemically mixed with other metallic.

A multiple stage milling operation reduces the calcined material to a small particle size.

By making the ceramic magnets out of carefully created mixtures more powerful magnet fields than were possible in nature could be generated.

They are composed of iron oxide and strontium carbonate.

They are made from strontium or barium ferrite.

Ceramic magnet manufacturing methods.

For example barium hexaferrite ceramic magnets used commonly as seals on refrigerator doors are polycrystalline materials in which only the 00l crystallite directions have a magnetic moment.